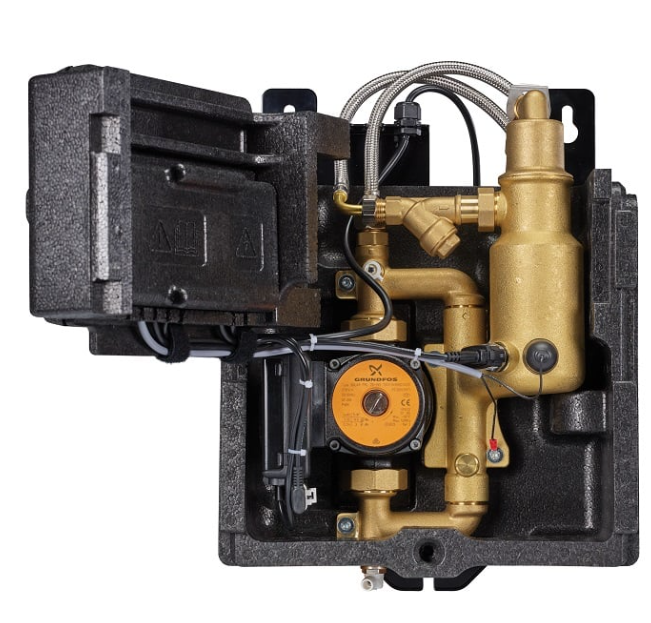

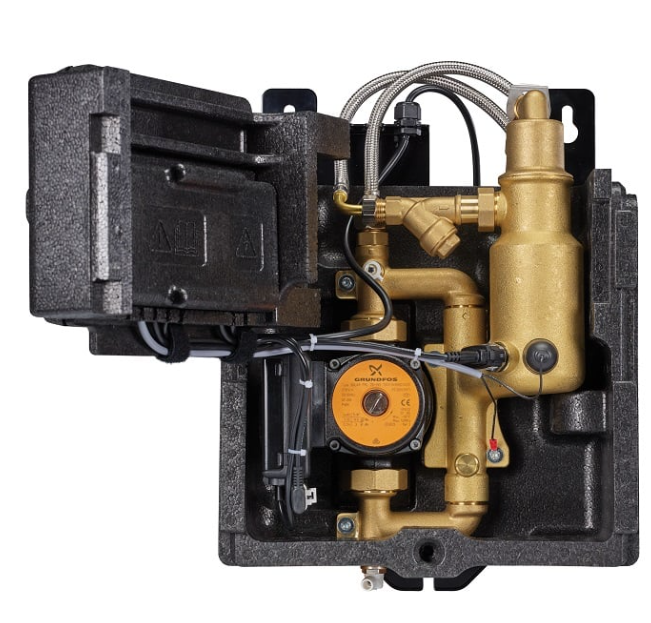

EPP is an excellent material choice for HVAC structural parts because it can be molded into complex shapes without losing its resiliency.The design flexibility of EPP enables key system components such as pumps, boilers, valves, heat-exchangers and control mechanisms to be universally housed in EPP to improve their insulation.

Using Expanded Polypropylene (EPP) foam for HVAC (Heating, Ventilation, and Air Conditioning) structure casing offers several advantages in terms of insulation, durability, and customization.

Here's how can be beneficial for HVAC structure casing:

1. **Insulation Properties**: EPP foam has excellent thermal insulation properties, helping to prevent heat transfer between the HVAC components and

the surrounding environment. By minimizing heat loss or gain, EPP foam casing helps improve energy efficiency and maintain optimal operating

conditions for HVAC systems.

2. **Lightweight Construction**: EPP foam is lightweight yet structurally robust, making it easy to handle and install as casing for HVAC components. Its lightweight nature reduces the overall weight of the HVAC system, which can be beneficial for transportation, installation, and structural support requirements.

3. **Impact Resistance**: EPP foam is known for its impact resistance, providing protection to HVAC components against accidental impacts or vibrations during operation or maintenance activities. This helps to prolong the lifespan of HVAC equipment and reduce the risk of damage.、

4 **Moisture Resistance**: EPP foam is inherently resistant to moisture, preventing water absorption and mold growth. This feature is particularly advantageous for HVAC casing applications where exposure to humidity or moisture is a concern, ensuring long-term durability and performance.

5. **Chemical Resistance**: EPP foam exhibits resistance to a wide range of chemicals, including oils, solvents, and cleaning agents commonly used in HVAC systems. This chemical resistance helps maintain the integrity of the casing and protects HVAC components from corrosive substances.

6. **Recyclability**: EPP foam is recyclable, contributing to sustainability initiatives in the HVAC industry by reducing waste and promoting the use of eco-friendly materials. At the end of its service life, EPP foam casing can be recycled or reused, minimizing environmental impact.

EPP is an excellent material choice for HVAC structural parts because it can be molded into complex shapes without losing its resiliency.The design flexibility of EPP enables key system components such as pumps, boilers, valves, heat-exchangers and control mechanisms to be universally housed in EPP to improve their insulation.

Using Expanded Polypropylene (EPP) foam for HVAC (Heating, Ventilation, and Air Conditioning) structure casing offers several advantages in terms of insulation, durability, and customization.

Here's how can be beneficial for HVAC structure casing:

1. **Insulation Properties**: EPP foam has excellent thermal insulation properties, helping to prevent heat transfer between the HVAC components and

the surrounding environment. By minimizing heat loss or gain, EPP foam casing helps improve energy efficiency and maintain optimal operating

conditions for HVAC systems.

2. **Lightweight Construction**: EPP foam is lightweight yet structurally robust, making it easy to handle and install as casing for HVAC components. Its lightweight nature reduces the overall weight of the HVAC system, which can be beneficial for transportation, installation, and structural support requirements.

3. **Impact Resistance**: EPP foam is known for its impact resistance, providing protection to HVAC components against accidental impacts or vibrations during operation or maintenance activities. This helps to prolong the lifespan of HVAC equipment and reduce the risk of damage.、

4 **Moisture Resistance**: EPP foam is inherently resistant to moisture, preventing water absorption and mold growth. This feature is particularly advantageous for HVAC casing applications where exposure to humidity or moisture is a concern, ensuring long-term durability and performance.

5. **Chemical Resistance**: EPP foam exhibits resistance to a wide range of chemicals, including oils, solvents, and cleaning agents commonly used in HVAC systems. This chemical resistance helps maintain the integrity of the casing and protects HVAC components from corrosive substances.

6. **Recyclability**: EPP foam is recyclable, contributing to sustainability initiatives in the HVAC industry by reducing waste and promoting the use of eco-friendly materials. At the end of its service life, EPP foam casing can be recycled or reused, minimizing environmental impact.