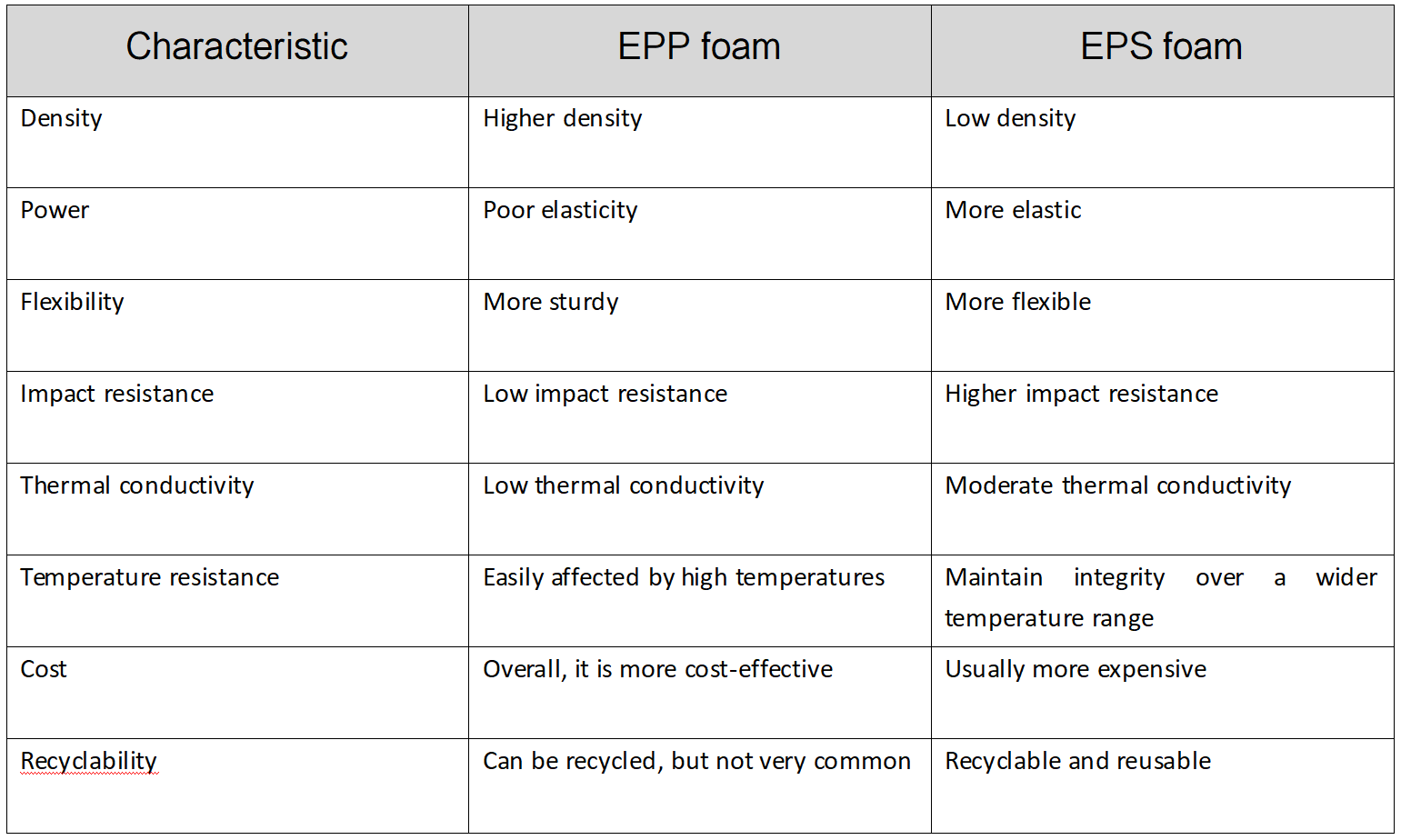

Density:

Compared with , EPS foam usually has higher density, so it is harder but less flexible.

Strength and durability:

EPP foam has higher strength and durability, making it suitable for applications requiring repeated impact.

Impact resistance:

Compared with EPS foam, EPP foam has better impact resistance, making it an ideal choice for protective packaging and auto parts.

Temperature resistance:

EPS foam will degrade at high temperature, while EPP foam can maintain its structural integrity in a wider temperature range, and is suitable for use in extreme environments.

Cost:

EPS foam is usually more cost-effective than EPP foam, making it the first choice for budget focused projects.

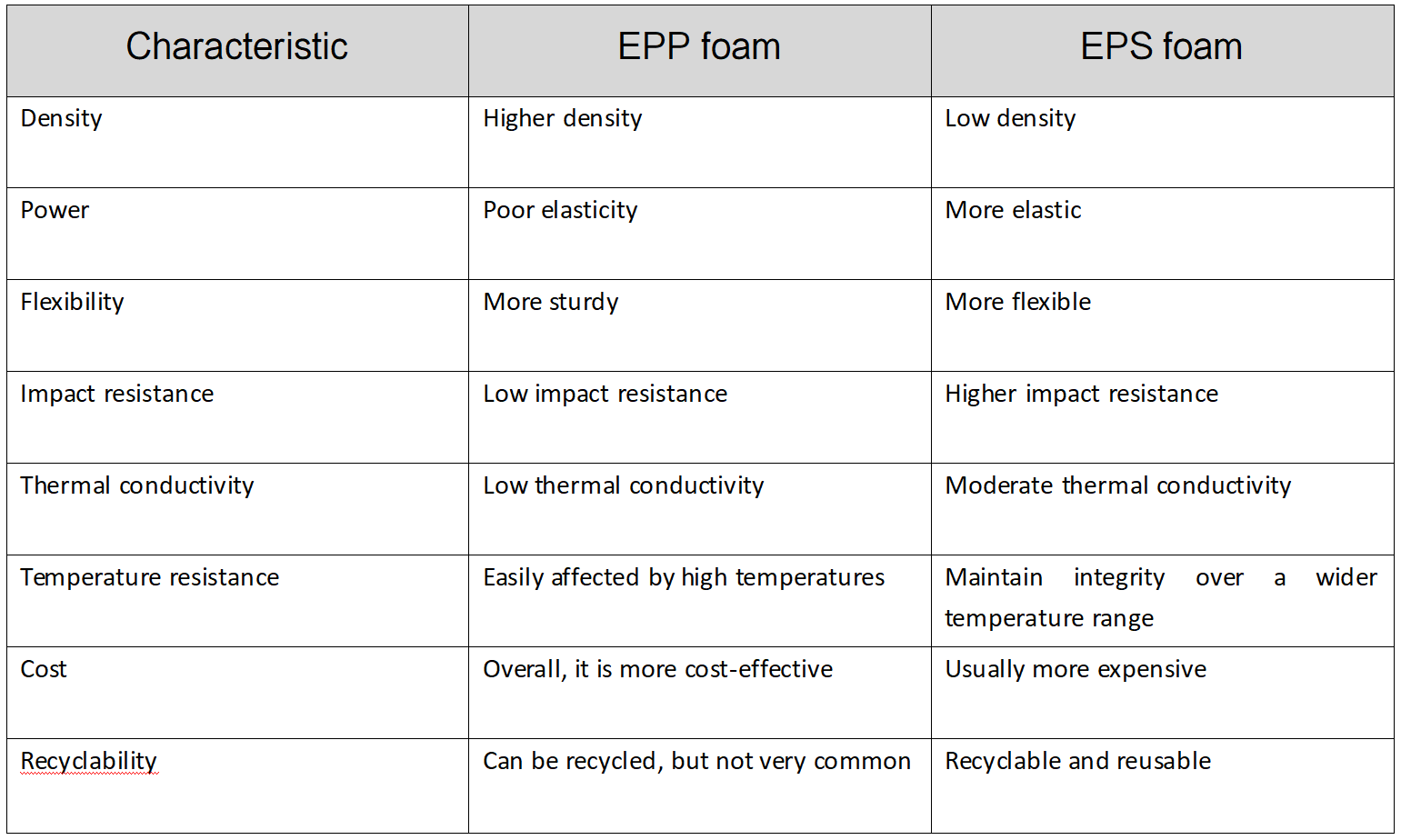

Density:

Compared with , EPS foam usually has higher density, so it is harder but less flexible.

Strength and durability:

EPP foam has higher strength and durability, making it suitable for applications requiring repeated impact.

Impact resistance:

Compared with EPS foam, EPP foam has better impact resistance, making it an ideal choice for protective packaging and auto parts.

Temperature resistance:

EPS foam will degrade at high temperature, while EPP foam can maintain its structural integrity in a wider temperature range, and is suitable for use in extreme environments.

Cost:

EPS foam is usually more cost-effective than EPP foam, making it the first choice for budget focused projects.