CNC prototyping is a process that uses CNC machines to quickly produce prototypes. It plays a crucial role in product development as it allows manufacturers to create visual and functional replicas of the final product with a high degree of accuracy and precision. By using CNC prototyping, manufacturers can identify and correct design flaws before large - scale production, which helps to reduce costs and improve product quality.

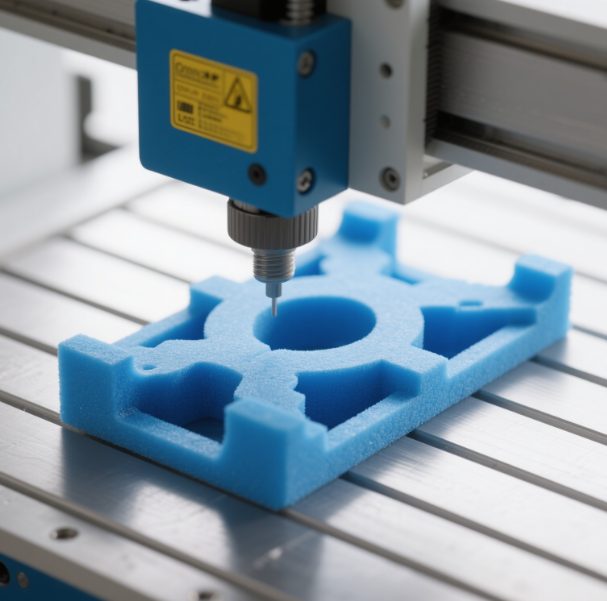

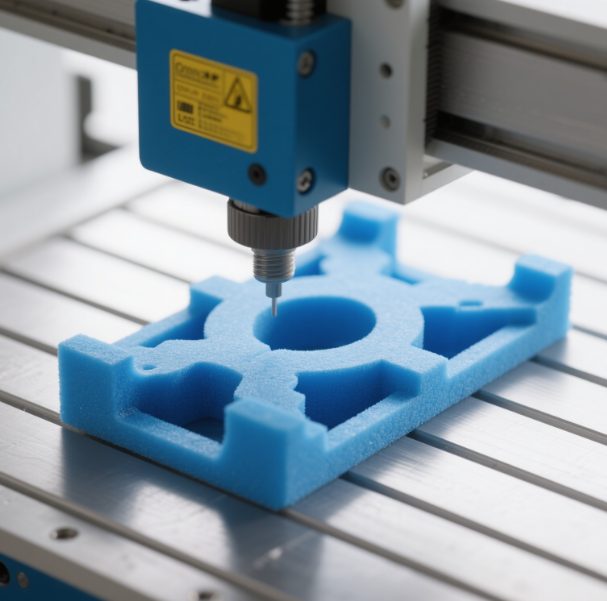

The process of CNC prototyping typically starts with creating a 3D CAD model of the desired product. This model is then converted into CAM files, which store the G - code that directs the movement of the CNC machine during the prototyping process. The CNC machine cuts and shapes the raw material according to the instructions in the G - code, gradually forming the prototype.

The process of CNC prototyping typically starts with creating a 3D CAD model of the desired product. This model is then converted into CAM files, which store the G - code that directs the movement of the CNC machine during the prototyping process. The CNC machine cuts and shapes the raw material according to the instructions in the G - code, gradually forming the prototype.

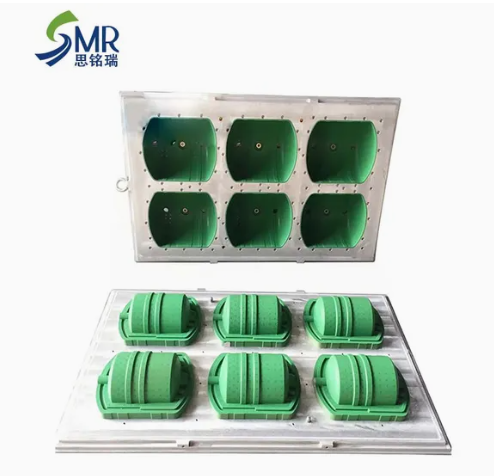

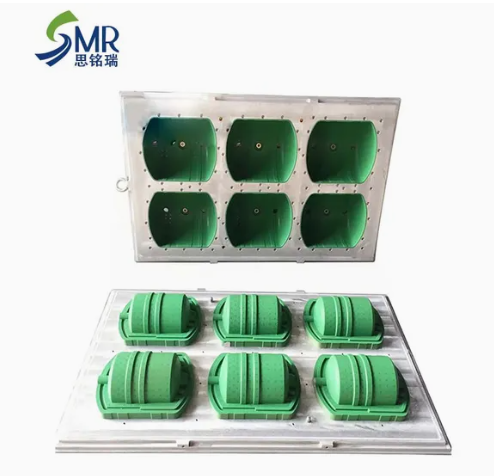

Regarding Simingrui's CNC prototypes, Simingrui is a well - known company in the field of precision technology. They specialize in the research and development, production, and sales of EPP (Expanded Polypropylene) foam products. Their EPP foam CNC prototypes have several notable features. EPP foam is a high - performance material with excellent shock - absorption, lightweight, and environmental - friendly properties. Simingrui's EPP CNC prototypes can fully utilize the advantages of EPP material. Thanks to the precise control of the CNC machine, the prototypes can achieve complex shapes and accurate dimensions, meeting various design requirements. Whether it is for packaging, automotive interiors, or sports equipment, Simingrui's EPP CNC prototypes can provide reliable solutions. In addition, Simingrui has a professional R & D team and advanced production equipment. They can provide customers with customized services, promptly providing the best design solutions and samples according to customers' needs. This enables them to have a strong competitive advantage in the market.

Regarding Simingrui's CNC prototypes, Simingrui is a well - known company in the field of precision technology. They specialize in the research and development, production, and sales of EPP (Expanded Polypropylene) foam products. Their EPP foam CNC prototypes have several notable features. EPP foam is a high - performance material with excellent shock - absorption, lightweight, and environmental - friendly properties. Simingrui's EPP CNC prototypes can fully utilize the advantages of EPP material. Thanks to the precise control of the CNC machine, the prototypes can achieve complex shapes and accurate dimensions, meeting various design requirements. Whether it is for packaging, automotive interiors, or sports equipment, Simingrui's EPP CNC prototypes can provide reliable solutions. In addition, Simingrui has a professional R & D team and advanced production equipment. They can provide customers with customized services, promptly providing the best design solutions and samples according to customers' needs. This enables them to have a strong competitive advantage in the market.

CNC prototyping is a process that uses CNC machines to quickly produce prototypes. It plays a crucial role in product development as it allows manufacturers to create visual and functional replicas of the final product with a high degree of accuracy and precision. By using CNC prototyping, manufacturers can identify and correct design flaws before large - scale production, which helps to reduce costs and improve product quality.

The process of CNC prototyping typically starts with creating a 3D CAD model of the desired product. This model is then converted into CAM files, which store the G - code that directs the movement of the CNC machine during the prototyping process. The CNC machine cuts and shapes the raw material according to the instructions in the G - code, gradually forming the prototype.

The process of CNC prototyping typically starts with creating a 3D CAD model of the desired product. This model is then converted into CAM files, which store the G - code that directs the movement of the CNC machine during the prototyping process. The CNC machine cuts and shapes the raw material according to the instructions in the G - code, gradually forming the prototype.

Regarding Simingrui's CNC prototypes, Simingrui is a well - known company in the field of precision technology. They specialize in the research and development, production, and sales of EPP (Expanded Polypropylene) foam products. Their EPP foam CNC prototypes have several notable features. EPP foam is a high - performance material with excellent shock - absorption, lightweight, and environmental - friendly properties. Simingrui's EPP CNC prototypes can fully utilize the advantages of EPP material. Thanks to the precise control of the CNC machine, the prototypes can achieve complex shapes and accurate dimensions, meeting various design requirements. Whether it is for packaging, automotive interiors, or sports equipment, Simingrui's EPP CNC prototypes can provide reliable solutions. In addition, Simingrui has a professional R & D team and advanced production equipment. They can provide customers with customized services, promptly providing the best design solutions and samples according to customers' needs. This enables them to have a strong competitive advantage in the market.

Regarding Simingrui's CNC prototypes, Simingrui is a well - known company in the field of precision technology. They specialize in the research and development, production, and sales of EPP (Expanded Polypropylene) foam products. Their EPP foam CNC prototypes have several notable features. EPP foam is a high - performance material with excellent shock - absorption, lightweight, and environmental - friendly properties. Simingrui's EPP CNC prototypes can fully utilize the advantages of EPP material. Thanks to the precise control of the CNC machine, the prototypes can achieve complex shapes and accurate dimensions, meeting various design requirements. Whether it is for packaging, automotive interiors, or sports equipment, Simingrui's EPP CNC prototypes can provide reliable solutions. In addition, Simingrui has a professional R & D team and advanced production equipment. They can provide customers with customized services, promptly providing the best design solutions and samples according to customers' needs. This enables them to have a strong competitive advantage in the market.